Painstaking Lessons Of Info About How To Check Pinion Depth

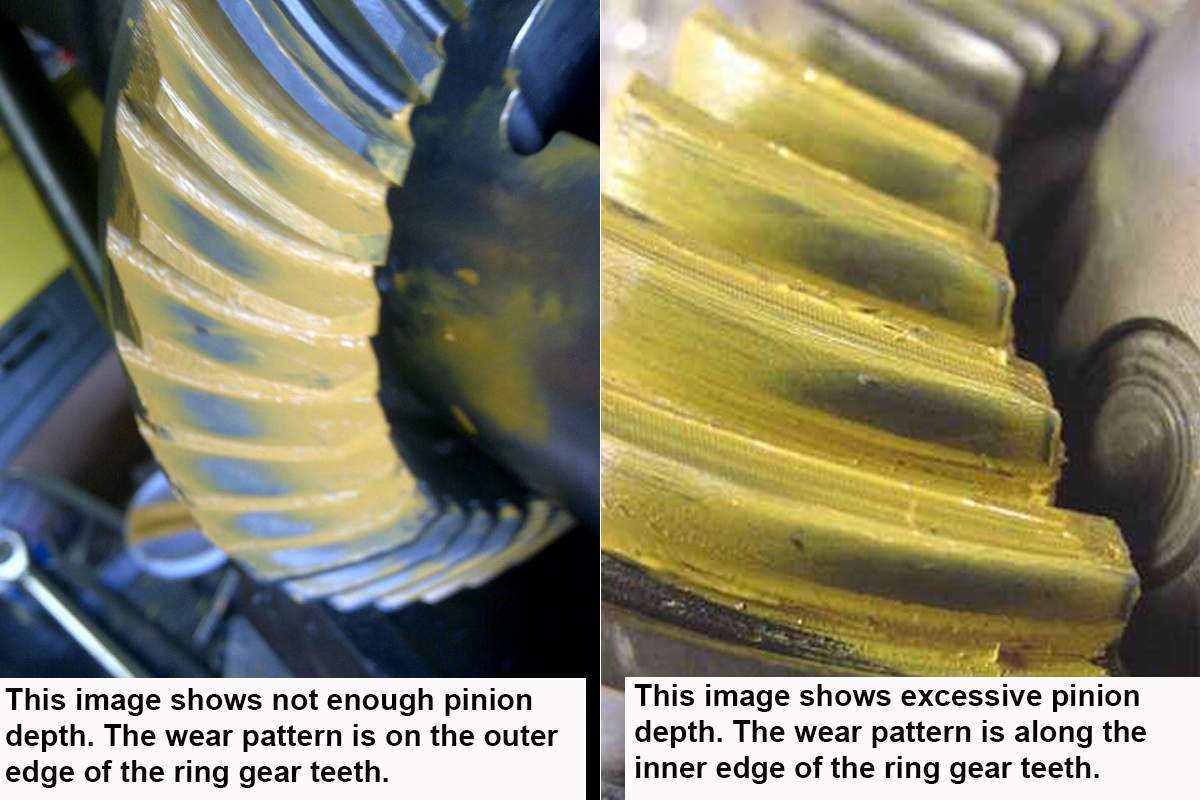

And it will eventually chew up the gears.

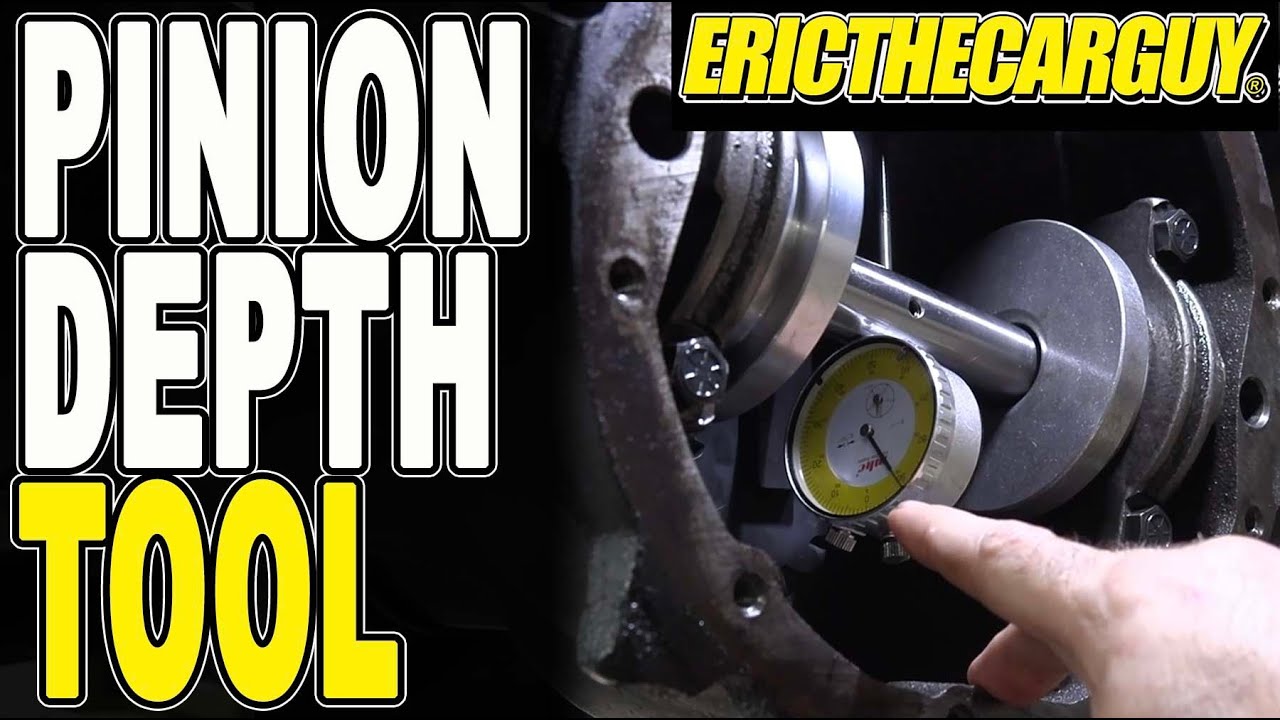

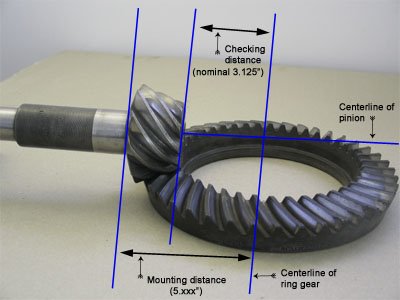

How to check pinion depth. If you don't have experience reading the. There is a small step on the back of the pinion that extends.035 past the rear edge of the tooth. For me, using a pinion depth gauge is the best way to measure pinion depth and finding the perfect pinion shim.

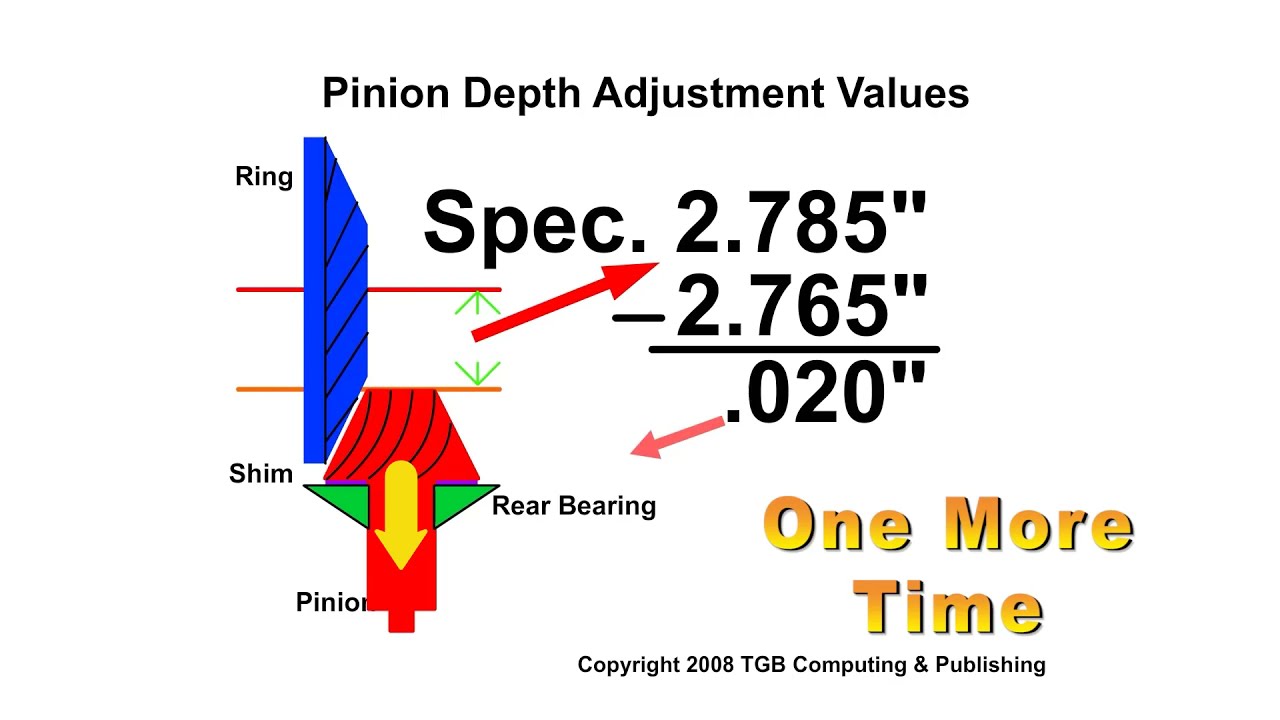

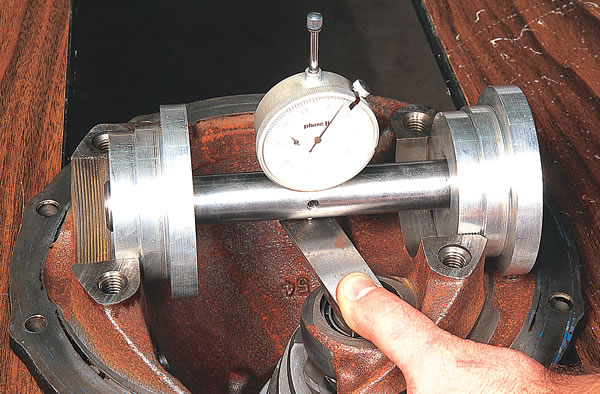

The way that the pinion depth tool works is by measuring from the center line of the differential bearing to the face of the pinion gear. If you press on the cage area the cage can disstort and allow the rollers to fall out (worse case). This gives me a reference as to the.

How to use the t & d universal pinion depth gauge to measure pinion depth on all stand alone differentials that are not part of a transaxle. Ok.i just called the manufacturer.they said none of the markings relate to setup or pinion depth.they did suggest starting at 2.312.using the t&d method i came up with. (a typical preload torque would be.

Start with the original shim that came in the rear end and do a pattern check. I screw it real close to the pinion, about.025, and lock it down. The distance to the pinion bearing seat is.

In order to set pinion depth correctly, you will need to spend around $40, and you get to keep the tools to use later, including the dial calipers : New posi carrier, new ring gear, new pinion, new bearings, new axles, etc. I also round off the measuring end.

My question is do i. Put the carrier in, check my. It’s way more accurate than going by gear too.